The Case 800 and 1000 Crawler-dozers, manufactured between 1957 and 1959, were powerful and versatile crawler machines designed for heavy-duty earthmoving, loading, and dozing applications. With rugged construction, robust engines, and simple yet durable systems, these models were engineered to serve in demanding industrial and agricultural environments.

General Specifications

The Case 800 delivered 80 gross horsepower (72 net) with an operating weight well-suited for medium-scale dozing and loading. The larger Case 1000 provided 100 gross horsepower, offering additional strength for heavier operations. Both machines were built as dual-purpose loader-dozers, combining versatility with durability.

Engine

The Case 800 was powered by a Continental 4.5 L, 4-cylinder diesel engine, while the Case 1000 featured a larger 6.3 L, 4-cylinder diesel. Both engines provided steady torque and reliable performance, with the 1000 supplying increased horsepower for more demanding applications.

Fuel System

Fuel systems on both models were designed for continuous operation, providing reliable fuel delivery to support extended shifts under load. The larger displacement of the 1000 enabled longer duty cycles between refueling compared to the 800.

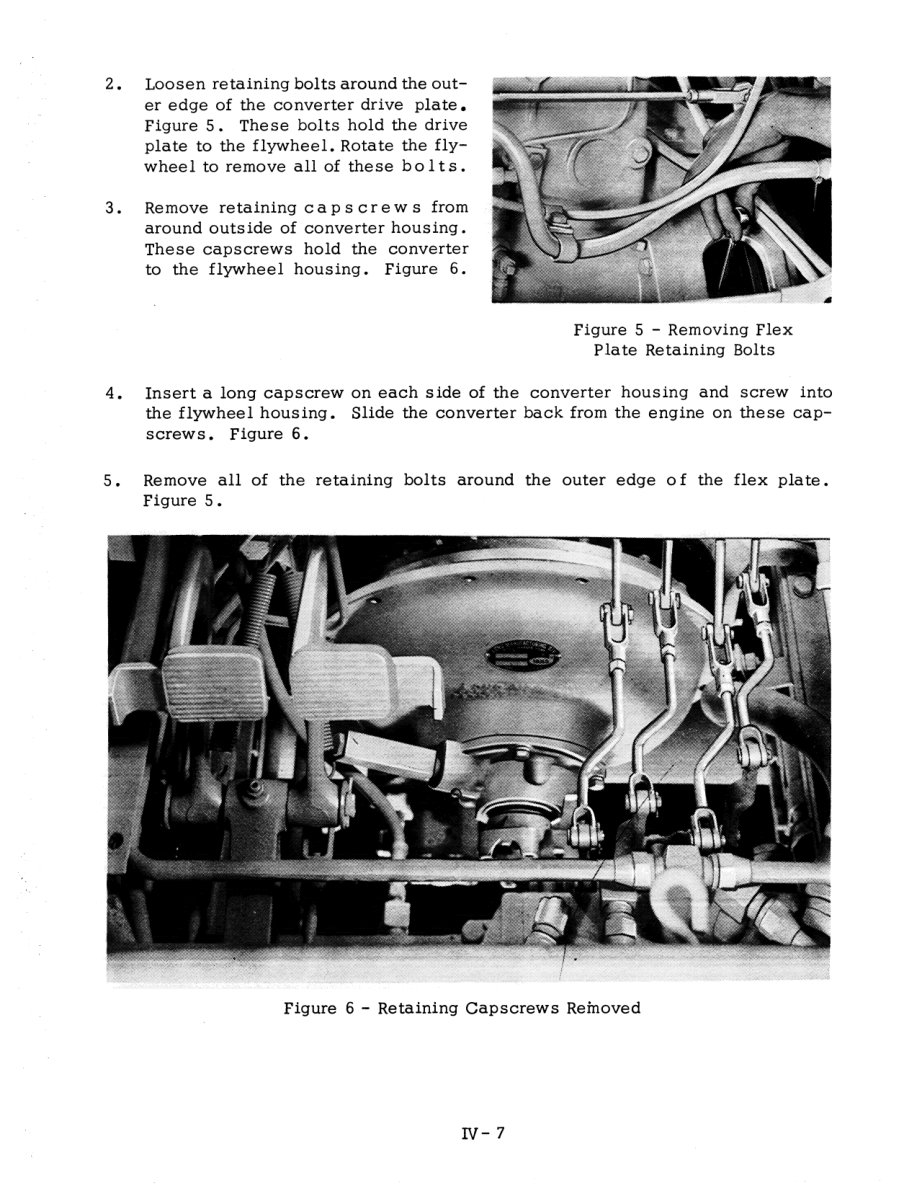

Torque Converter

The Case 800 was equipped with a torque converter, providing smooth power delivery and more efficient control during Crawler operations. The Case 1000, while using a direct 4-speed system, delivered strong and steady power transfer for heavier dozing applications.

Transmission

Both models were built with 4-speed transmissions. The torque converter drive in the 800 gave operators more flexibility in handling variable loads, while the 1000’s transmission was built to harness its higher horsepower output.

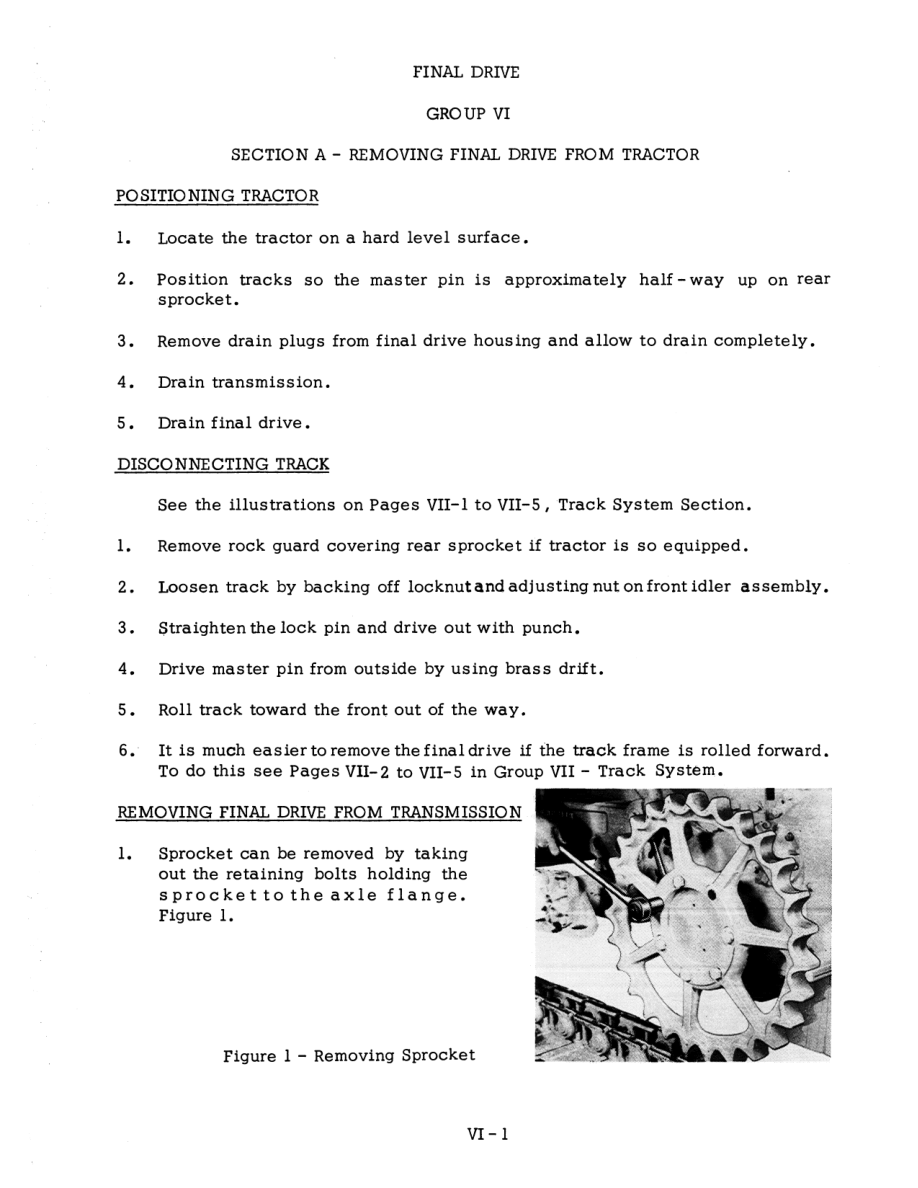

Final Drive System

Heavy-duty final drives were designed to withstand the stress of continuous pushing and lifting. The 1000’s larger drivetrain components were scaled to handle its higher power output and operating demands.

Track System

Both machines featured crawler track undercarriages, designed for traction and flotation. The track systems were engineered to distribute weight effectively, providing stability on uneven terrain. The heavier Case 1000 used reinforced track components to match its higher capacity.

Hydraulic System

The open-center hydraulic systems supported loader arms and dozer blade functions. The 800’s hydraulics were matched to its mid-size capacity, while the 1000 used a higher-volume system to handle heavier loads and attachments efficiently.

Key Highlights

- Production years: 1957 – 1959

- Case 800: Continental 4.5 L 4-cyl diesel, 80 HP gross / 72 HP net, torque converter drive

- Case 1000: Continental 6.3 L 4-cyl diesel, 100 HP gross, 4-speed transmission

- Both models designed as crawler loader-dozers with versatile applications

- Open-center hydraulic systems for blade and loader arm operation

- Heavy-duty track systems for stability and traction

- Final drives engineered for long service life under heavy loads

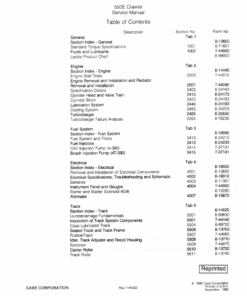

Table of Content

📙 Table of Contents

Table Of Contents

- Table of Contents

General Specifications

- General Specifications

Engine

- Engine

Fuel System

- Fuel System

Torque Converter

- Torque Converter

Transmission

- Transmission

Final Drive System

- Final Drive System

Track System

- Track System

Hydraulic System

- Hydraulic System

Specification

| Specification | Case 800 Crawler-Dozer | Case 1000 Crawler-Dozer |

|---|---|---|

| Years Produced | 1957 – 1959 | 1957 – 1959 |

| Model Type | Industrial crawler dozer | Industrial crawler dozer |

| Engine Manufacturer / Type | Continental 4.5 L 4-cyl diesel | Continental 6.3 L 4-cyl diesel |

| Engine Power (Horsepower) | 80 HP gross (72 HP net) | 100 HP gross |

| Transmission | 4-speed, torque converter | 4-speed |

| Operator Station | Open operator station | Industrial operator station |

Buyer Questions & Answers

Frequently Asked Questions❔

Are the manuals OEM (Original Equipment Manufacturer)?

- Yes, we only provide manuals that are sourced from the machine manufacturer or authorized dealers.

What file format are the manuals in?

- All manuals are provided in PDF format, which you can be open on your browser, computer, smartphone, or tablet.

- Printed versions are available for select manuals — check the product page or contact us for availability.

Is the manual printable?

- Yes, all pages are printable.

Where do I download the manual after I have paid for it?

- You’ll receive two emails:

- “Your order XXXXX has been received!” – sent immediately.

- “Your order XXXXX is now completed.” – sent within 12 hours with your secure download link.

- If you didn’t get the email:

- ✅ Log In to your Account and check your orders.

- 📂 Check your spam/junk folder.

- 📧 Make sure you didn’t use a different email during checkout.

Still have questions?

- Please Contact Us if you need assistance or have suggestions.

Only logged in customers who have purchased this product may leave a review.

Reviews

There are no reviews yet.