Case 750M Crawler Dozer Repair Manual

$35.00

| 🚜 Equipment | |||

|---|---|---|---|

| Brand | CASE | ||

| Type | Crawler Dozer | ||

| Model | 750M | ||

| 📄 Documents | |||

| Language | English | ||

| Format | |||

| Title | Serial | Publication No. | Pages |

| Repair Manual Tier 4A (interim) | SN NHC101150 and above | 48080038 | 2011 |

| Repair Manual Tier 4B (final) | SN NCDC75000 and above SN NDDC7000 and above SN NEDC70000 and above SN NFDC7000 and above SN NFC101000 and above

| 51418565 | 2007 |

- Description

- Additional information

- Table of Content

- Specification

- Buyer Questions & Answers

- Reviews (0)

The Case 750M crawler dozer is part of Case’s M-Series lineup, built to combine advanced hydrostatic drive technology, fuel-efficient Tier 4 Final engines, and operator-focused comfort features. Designed for grading, dozing, and site-preparation work, the 750M offers a balance of maneuverability and productivity with multiple track and blade configurations. With operating weights between 20,300 and 21,500 lb, it is a versatile mid-size dozer well-suited to construction, utility, and land-clearing applications.

Introduction

The Case 750M was engineered for maximum efficiency and ease of operation. Its dual-path hydrostatic transmission provides infinitely variable speed control and counter-rotation, while the six-way PAT blade ensures precise control for dozing and grading operations. Combined with modern cab features and simple maintenance points, the machine delivers both productivity and operator comfort.

Maintenance – 00

Service access points are designed for ease of maintenance, with grouped filters, ground-level fueling, and simplified lubrication. This reduces downtime and enhances overall serviceability.

Engine – 10

The 750M is powered by a 6.7 L FPT (Fiat Powertrain) six-cylinder turbocharged diesel engine, compliant with Tier 4 Final emissions. It produces 112 gross horsepower (92 net HP) with peak torque of ~332 lb-ft at 1,400 rpm. The engine is optimized for fuel efficiency and responsive torque delivery.

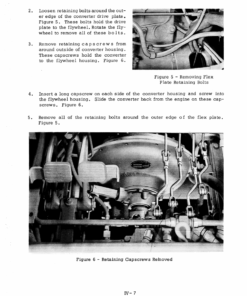

Power Coupling – 19

The engine couples directly to the hydrostatic drive system, ensuring smooth, efficient power transfer with minimal loss. This setup provides excellent tractive effort and precise machine control.

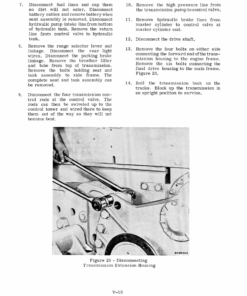

Hydrostatic Drive – 29

A dual-path hydrostatic transmission delivers independent power to each track, allowing counter-rotation and tight turning. Operators benefit from infinite speed adjustment up to ~5.8 mph, giving full control for both heavy pushing and fine grading applications.

Brakes And Controls – 33

Dynamic hydrostatic braking is supported by hydraulic wet-disc service brakes. Fingertip controls with electro-hydraulic responsiveness ensure smooth machine handling with reduced operator fatigue.

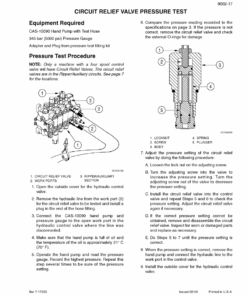

Hydraulic Systems – 35

The open-center hydraulic system provides a flow of ~20.6 GPM at 3,000 psi. With a 15.8-gallon hydraulic reservoir, the system delivers consistent blade movement and auxiliary power, supporting efficient dozer operation under load.

Tracks And Track Suspension – 48

The undercarriage includes six bottom rollers per side, with 39 shoes per side. Track shoe widths range from 18 to 30 inches depending on configuration (XLT, WT, or LGP). Ground pressure varies from 5.8 psi (XLT) to as low as 4.5 psi (LGP), enabling stable operation across firm and soft soils.

Cab Climate Control – 50

The cab is ROPS/FOPS-certified and offers excellent visibility. Heating, ventilation, and optional air conditioning provide comfort in all weather conditions, while ergonomic controls and a low-noise design improve operator efficiency.

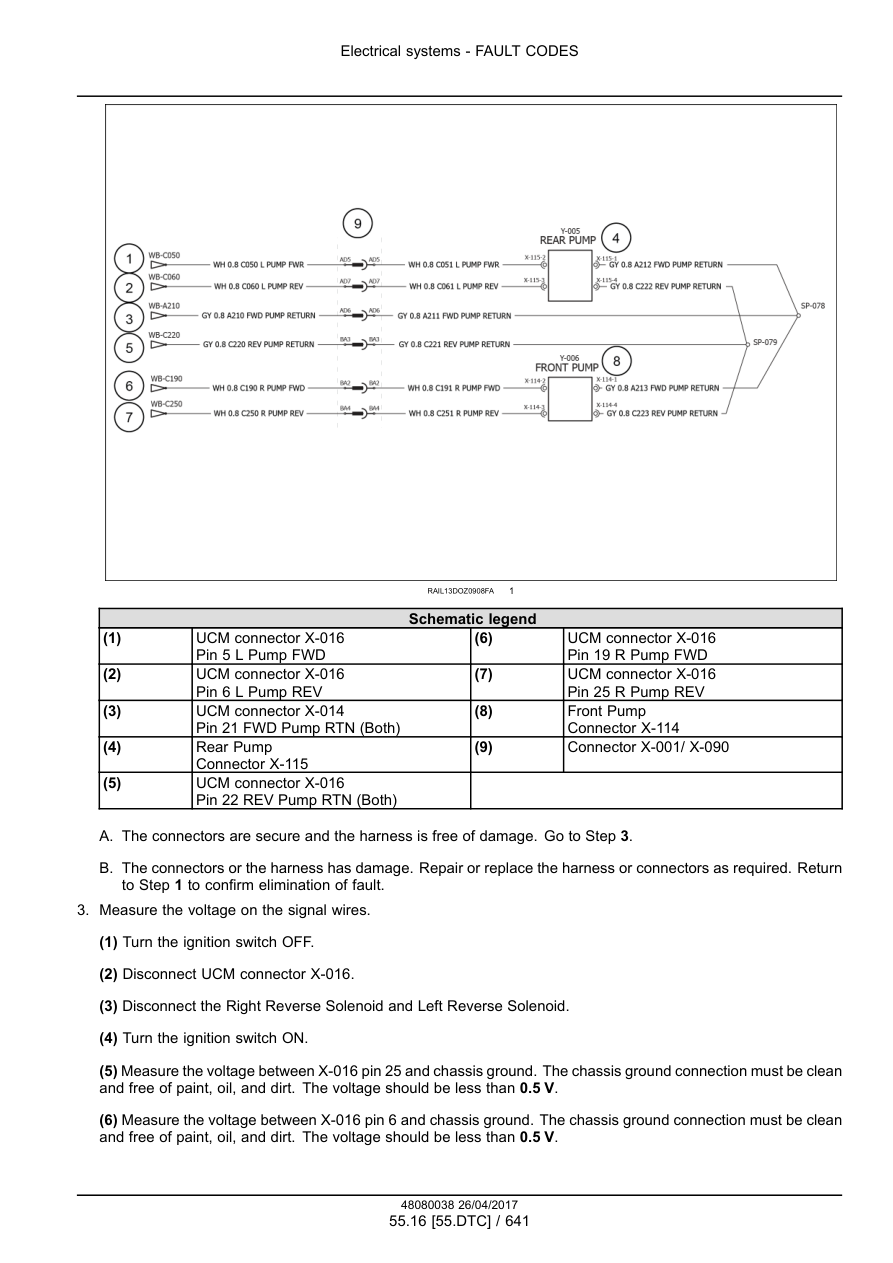

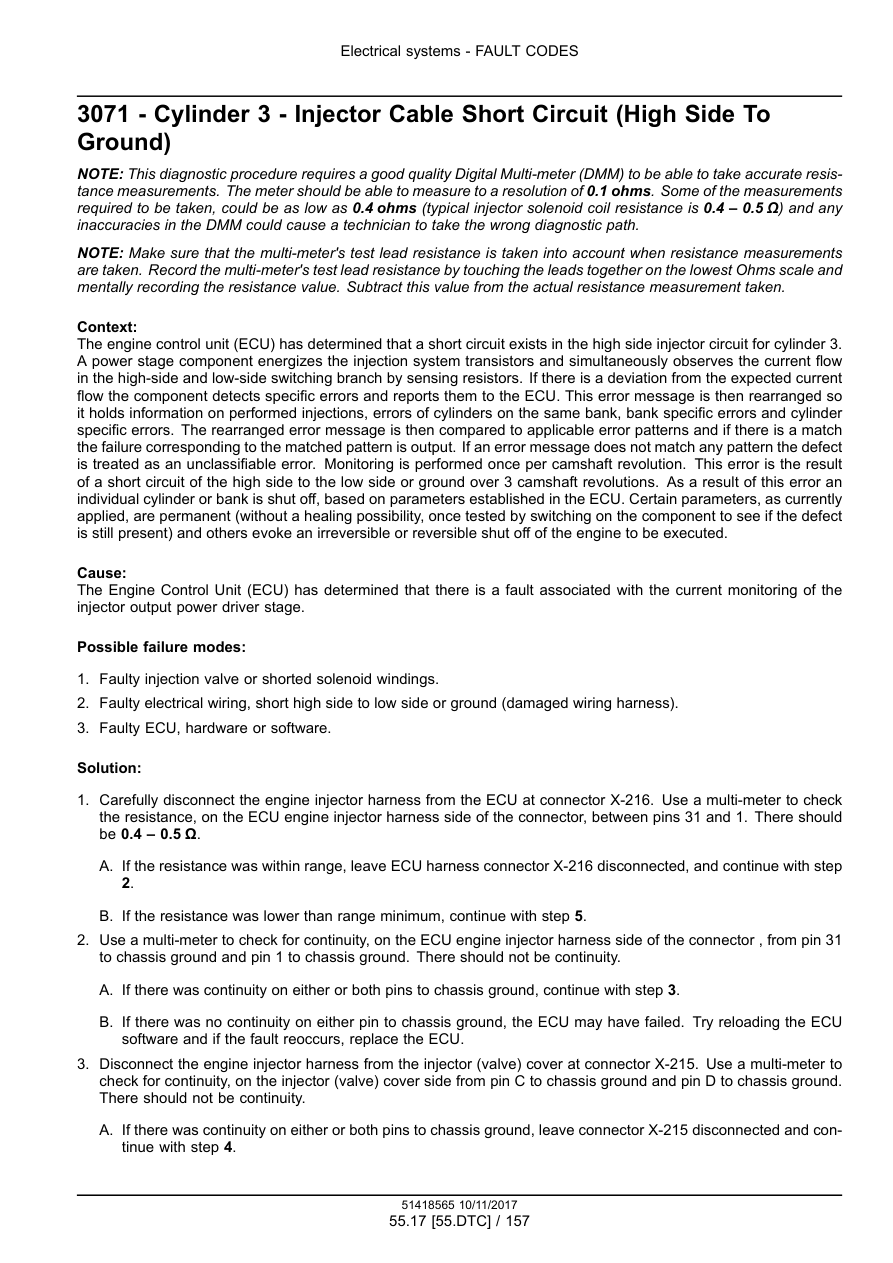

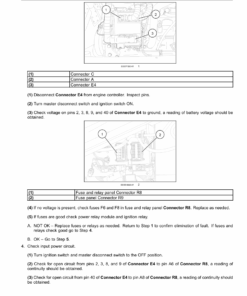

Electrical Systems – 55

The 750M is equipped with a 24-volt electrical system with dual 12-volt batteries and a 100-amp alternator. This ensures reliable engine starting and powers all lighting, diagnostics, and auxiliary functions.

Lubrication System – 71

Centralized lubrication points simplify maintenance. The engine oil system has a capacity of ~4 gal, supporting proper lubrication under sustained operation.

Dozer Blade And Arm – 86

The standard six-way PAT blade has a heaped capacity of approximately 2.0–2.1 yd³, allowing precise material handling and efficient grading. The blade arms are designed for strength and durability under repeated heavy-duty cycles.

Tools – 89

Optional rear-mounted tools such as rippers and winches expand the machine’s capabilities for land clearing, site preparation, and utility applications.

Platform, Cab, Bodywork, And Decals – 90

The cab and platform are built for operator comfort and durability, with rugged exterior bodywork and clear Case M-Series branding. Easy entry, wide visibility, and intuitive controls enhance day-to-day usability.

Electrical Schematic – 48080044

The service manual includes full electrical schematics, covering circuits, wiring layouts, and troubleshooting guides for the 24V system.

Hydraulic Schematic – 48080048

The manual also provides detailed hydraulic schematics for diagnostics and repair of the hydrostatic and blade control systems.

Key Highlights

- Engine: FPT 6.7 L turbo diesel, 112 gross HP / 92 net HP, ~332 lb-ft torque

- Operating weight: 20,300 – 21,500 lb (depending on configuration)

- Transmission: Hydrostatic dual-path drive, variable speeds up to 5.8 mph

- Fuel capacity: 51.5 gallons; Hydraulic capacity: 15.8 gallons

- Blade: Six-way PAT blade, ~2.0–2.1 yd³ capacity

- Track: 39 shoes per side, 18–30 in shoe width options

- Ground pressure: 5.8 psi (XLT) to 4.5 psi (LGP)

- Electrical: 24V system, dual 12V batteries, 100A alternator

- ROPS/FOPS cab with optional HVAC for operator comfort

- Optional rear tools: winch or ripper for extended functionality

| Publication | 48080038, 51418565 |

|---|

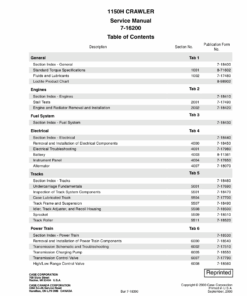

Table of Content

📙 Table of Contents – Publication Number 51418565

Contents

- Contents

Introduction

- INTRODUCTION

Maintenance – 00

- Maintenance – 00

Engine – 10

- Engine – 10

Power Coupling – 19

- Power coupling – 19

Hydrostatic Drive – 29

- Hydrostatic drive – 29

Brakes And Controls – 33

- Brakes and controls – 33

Hydraulic Systems – 35

- Hydraulic systems – 35

Tracks And Track Suspension – 48

- Tracks and track suspension – 48

Cab Climate Control – 50

- Cab climate control – 50

Electrical Systems – 55

- Electrical systems – 55

Lubrication System – 71

- Lubrication system – 71

Dozer Blade And Arm – 86

- Dozer blade and arm – 86

Tools – 89

- Tools – 89

Platform, Cab, Bodywork, And Decals – 90

- Platform, cab, bodywork, and decals – 90

Special Tool Index

- SPECIAL TOOL INDEX

Electrical Schematic – 48080044

- ELECTRICAL SCHEMATIC – 48080044

Hydraulic Schematic – 48080048

- HYDRAULIC SCHEMATIC – 48080048

Specification

| Specification | Case 750M |

|---|---|

| Years Produced | 2013 – Present (M-Series) |

| Model Type | Crawler dozer (Available in XLT, WT, LGP) |

| Engine Manufacturer / Type | FPT (Fiat Powertrain) 6-cyl turbocharged diesel, Tier 4 Final |

| Displacement | 6.7 L (409 cu in) |

| Engine Power (Horsepower) | 92 kW (92 net HP / 112 gross HP) |

| Max Torque | ~332 lb-ft @ 1,400 rpm |

| Fuel Capacity | 51.5 gal (195 L) |

| Hydraulic Fluid Capacity | 15.8 gal (60 L) |

| Hydraulic System | Load-sensing, variable-displacement piston pump; 20.6 GPM @ 3,000 psi |

| Transmission | Hydrostatic dual-path drive with electronic control |

| Operating Weight | ~20,300 lb (XLT); ~21,500 lb (LGP) |

| Blade Capacity (Heaped) | ~2.0 – 2.1 yd³ (6-way PAT blade) |

| Track / Undercarriage | 39 shoes per side; 6 rollers; track shoe width: 18–30 in depending on variant |

| Dimensions (L × W × H) | Length (with blade) ~15.5 ft; Width ~8–10 ft; Height to cab ~9.8 ft |

| Ground Pressure | 5.8 psi (XLT); as low as 4.5 psi (LGP) |

| Electrical System | 24-volt system; dual 12V batteries; 100-amp alternator |

| Operator Station | ROPS/FOPS cab, ergonomic controls, optional HVAC |

Buyer Questions & Answers

Frequently Asked Questions❔

Are the manuals OEM (Original Equipment Manufacturer)?

- Yes, we only provide manuals that are sourced from the machine manufacturer or authorized dealers.

What file format are the manuals in?

- All manuals are provided in PDF format, which you can be open on your browser, computer, smartphone, or tablet.

- Printed versions are available for select manuals — check the product page or contact us for availability.

Is the manual printable?

- Yes, all pages are printable.

Where do I download the manual after I have paid for it?

- You’ll receive two emails:

- “Your order XXXXX has been received!” – sent immediately.

- “Your order XXXXX is now completed.” – sent within 12 hours with your secure download link.

- If you didn’t get the email:

- ✅ Log In to your Account and check your orders.

- 📂 Check your spam/junk folder.

- 📧 Make sure you didn’t use a different email during checkout.

Still have questions?

- Please Contact Us if you need assistance or have suggestions.

Only logged in customers who have purchased this product may leave a review.

Reviews

There are no reviews yet.