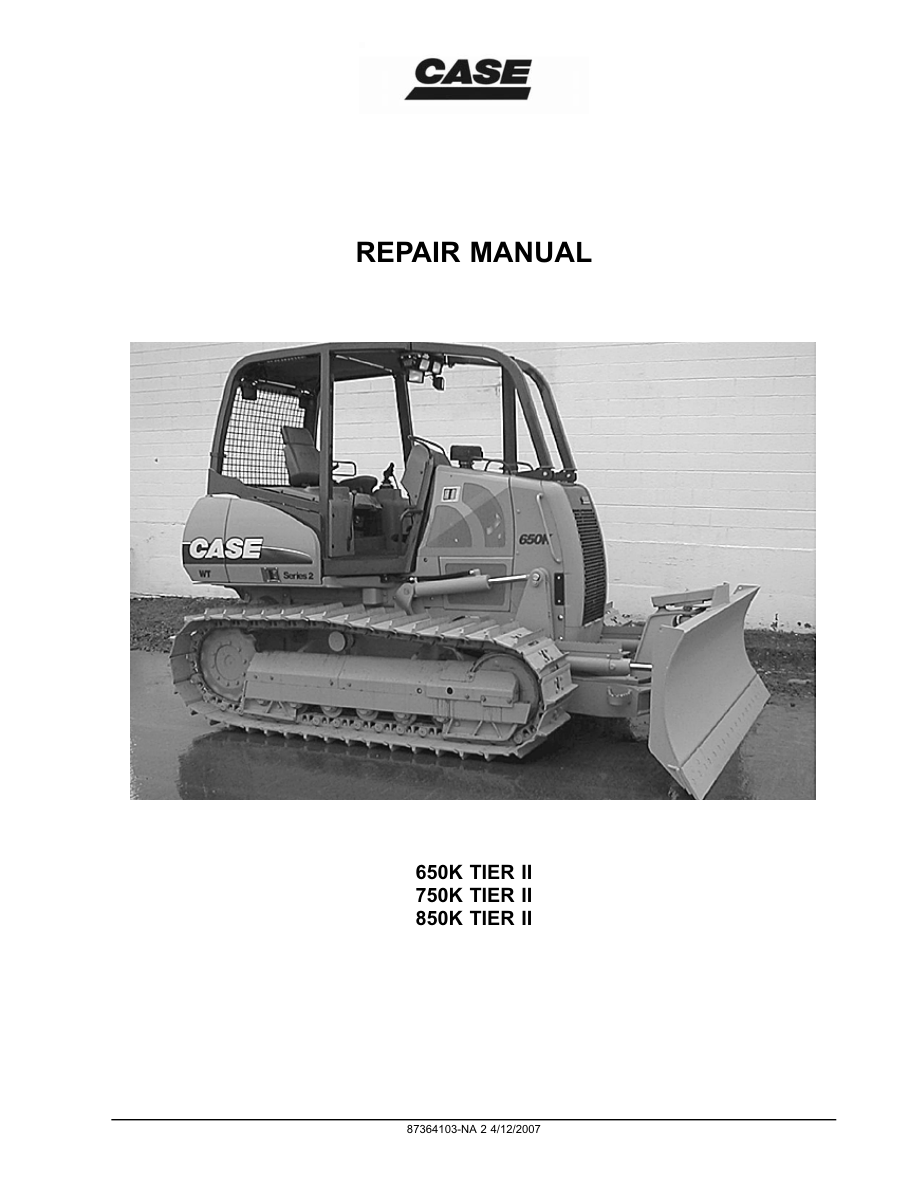

The Case 650K, 750K, and 850K crawler dozers are part of Case’s K-Series lineup, engineered for strength, efficiency, and operator-focused productivity. These mid-sized dozers provide excellent balance between horsepower, weight, and hydraulic responsiveness, making them ideal for construction, grading, land clearing, and site preparation.

Introduction

The 650K, 750K, and 850K combine rugged Case engineering with hydrostatic power delivery, ensuring smooth operation and precise control. Operating weights range from 18,200 lb on the 650K up to over 22,000 lb on the 850K, providing a stable platform for heavy pushing and grading.

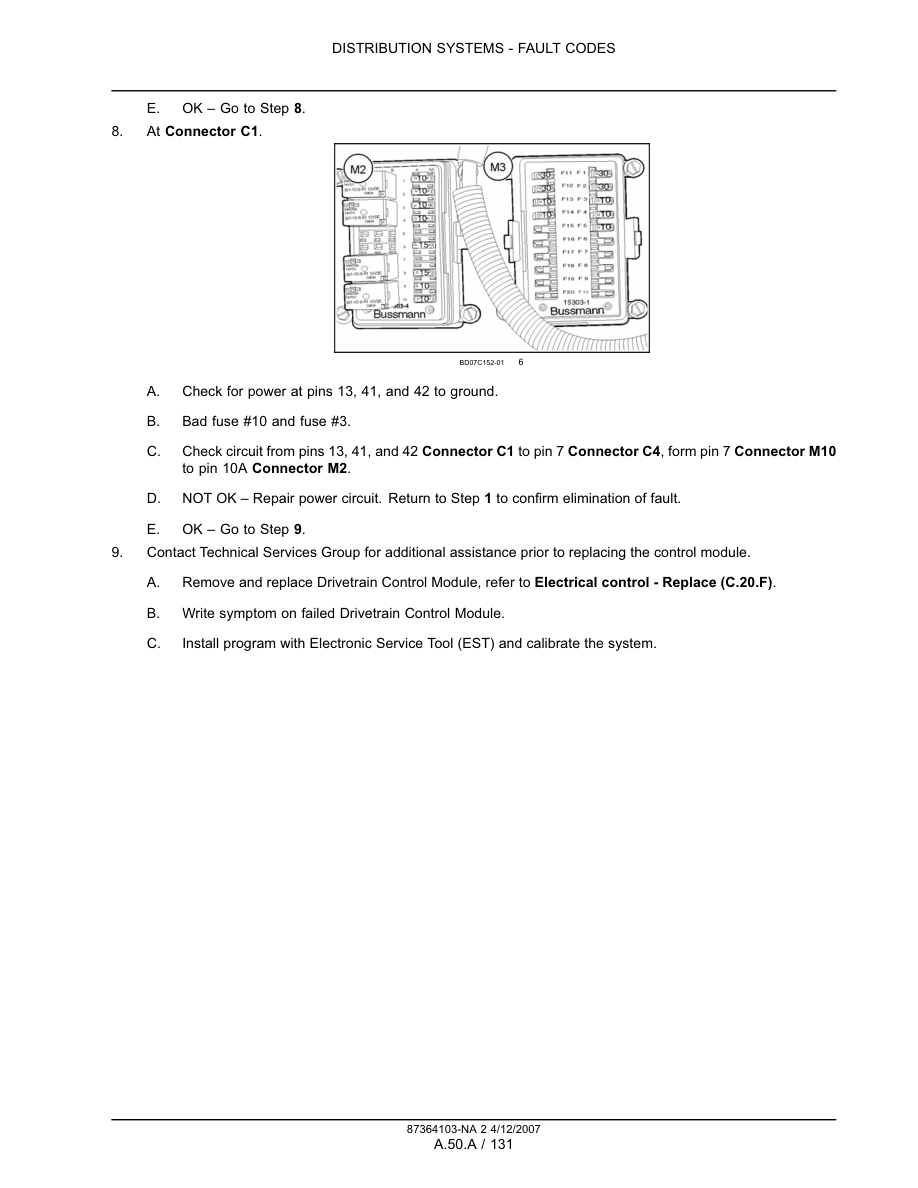

Distribution Systems

All three models utilize dual-path hydrostatic drive systems for power distribution, controlled through a single-lever joystick. This setup allows independent track control for excellent maneuverability, reduced operator fatigue, and efficient load handling in variable ground conditions.

Power Production

The Case 650K and 750K are powered by the Case Family III 445T/M2 4-cylinder diesel engine, delivering 80 HP (650K) and approximately 90–96 HP (750K). The larger 850K is equipped with the Case Family III 668T/M2 6-cylinder diesel engine, producing around 96 HP net. These Tier II compliant engines are designed for fuel efficiency, strong torque output, and long service life.

Power Train

A hydrostatic transmission provides infinite variable speeds up to 5.5 mph, enabling seamless adjustment to task requirements. The hydrostatic powertrain eliminates gear-shifting, offering smoother operation in both heavy dozing and fine grading applications.

Travelling

Track widths vary across the models: 16 in on the 650K, 18–20 in on the 750K, and 24 in on the 850K. Track ground contact spans approximately 88–110 in, ensuring strong traction and flotation in soft or uneven terrain. LGP (low ground pressure) configurations are available for sensitive soil conditions.

Body and Structure

The K-Series dozers feature robust mainframes and undercarriages designed for durability. Operator safety and comfort are enhanced with ROPS canopy options, ergonomic control placement, and excellent visibility for all-day productivity.

Tool Positioning

Blade control is responsive and precise, with fingertip joystick operation. PAT (power-angle-tilt) blades are standard on most configurations, offering multi-directional positioning for grading and finish work.

Working Arm

The dozers are fitted with straight or PAT blades, depending on the configuration. Capacities range from 2.0 yd³ on the 650K to 2.6 yd³ on the 850K. Blade widths vary from 8 ft to 9 ft, with lift and tilt functions supported by the hydraulic system.

Tools and Couplers

Rear-mounted ripper and winch options are available, extending the machine’s versatility for site clearing, soil preparation, and utility applications.

Electrical Schematics

A 12-volt negative ground system with a 65-amp alternator provides reliable starting and auxiliary electrical support. The system is designed for easy servicing and durability in demanding field environments.

Hydraulic Schematicas

The open-center hydraulic system delivers approximately 20–22 GPM at 3,025 psi (650K), with higher flow on the 750K and 850K models. A hydraulic reservoir capacity of 20 gal supports cooling and responsiveness, ensuring smooth blade and attachment control during sustained operations.

Key Highlights

- 650K: 80 HP 4-cyl diesel, ~18,200 lb, 16-in tracks, 2.0 yd³ blade

- 750K: ~90–96 HP 4-cyl diesel, ~18,900 lb, 18–20 in tracks, 2.3 yd³ blade

- 850K: ~96 HP 6-cyl diesel, ~22,000 lb, 24-in tracks, 2.6 yd³ blade

- Dual-path hydrostatic drive with single-lever control

- Fuel capacity up to 50 gallons; Hydraulic capacity up to 20 gallons

- Blade widths 8–9 ft with PAT (power-angle-tilt) configuration

- ROPS operator canopy with ergonomic controls

- Optional ripper and winch attachments for added versatility

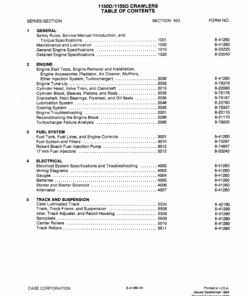

Table of Content

📙 Table of Contents

Table Of Content

- Table of Content

Introduction

- Introduction

Distribution Systems

- Distribution Systems

Power Production

- Power Production

Power Train

- Power Train

Travelling

- Travelling

Body And Structure

- Body and Structure

Tool Positioning

- Tool Positioning

Working Arm

- Working Arm

Tools And Couplers

- Tools and Couplers

Electrical Schematics

- Electrical Schematics

Hydraulic Schematicas

- Hydraulic Schematicas

Specification

| Specification | Case 650K | Case 750K | Case 850K |

|---|---|---|---|

| Years Produced | Early 2000s (K-Series) | Early 2000s (K-Series) | Early 2000s (K-Series) |

| Engine Manufacturer / Type | Case Family III 445T/M2 diesel, 4-cyl | Case Family III 445T/M2 diesel, 4-cyl | Case Family III 668T/M2 diesel, 6-cyl |

| Engine Power (Horsepower) | 80 HP gross / 75 HP net | — (net ~90–96 HP estimated) | — (net ~96 HP estimated) |

| Gross to Net HP Range | 75 HP net (from 80 HP gross) | ~96 HP net (based on series data) | ~96 HP net (based on series data) |

| Fuel Capacity | 50 gal | — | — |

| Hydraulic Fluid Capacity | 20 gal | — | — |

| Hydraulic System (Flow / Pressure) | ~21 GPM, ~3,025 psi | — | — |

| Operating Weight | Approx. 18,200 lb | Approx. 18,900 lb | Approx. 22,000 lb |

| Dimensions (L×W×H) | Length ~14 ft, Width ~6.1 ft, Height ~9.1 ft | Length ~16 ft 11 in, Width ~8 ft 7 in, Height ~9.1 ft | Length ~17 ft 2 in, Width ~8 ft 8 in, Height ~9.1 ft |

| Ground Contact (Track on Ground) | ~9 ft 2 in (110 in) | ~7.32 ft (~88 in) | — |

| Blade Capacity (Std.) | 2.1 yd³ | — | — |

Buyer Questions & Answers

Frequently Asked Questions❔

Are the manuals OEM (Original Equipment Manufacturer)?

- Yes, we only provide manuals that are sourced from the machine manufacturer or authorized dealers.

What file format are the manuals in?

- All manuals are provided in PDF format, which you can be open on your browser, computer, smartphone, or tablet.

- Printed versions are available for select manuals — check the product page or contact us for availability.

Is the manual printable?

- Yes, all pages are printable.

Where do I download the manual after I have paid for it?

- You’ll receive two emails:

- “Your order XXXXX has been received!” – sent immediately.

- “Your order XXXXX is now completed.” – sent within 12 hours with your secure download link.

- If you didn’t get the email:

- ✅ Log In to your Account and check your orders.

- 📂 Check your spam/junk folder.

- 📧 Make sure you didn’t use a different email during checkout.

Still have questions?

- Please Contact Us if you need assistance or have suggestions.

Only logged in customers who have purchased this product may leave a review.

Reviews

There are no reviews yet.