The Case 2550 crawler dozer, produced in the late 1970s through the mid-1980s, was the largest and most powerful crawler in Case’s lineup of that era. Built for mining, large-scale earthmoving, and land-clearing projects, the 2550 combined massive horsepower, heavy operating weight, and robust engineering to compete directly with other heavy crawler tractors of its generation. With an operating weight of nearly 88,000 lb and a blade capacity exceeding 10 cubic yards, it was designed for maximum productivity in the toughest conditions.

General

The Case 2550 was a large-frame crawler dozer weighing approximately 88,000 lb. With wide track options and heavy-duty undercarriage components, it provided stability, traction, and balance for demanding earthmoving applications.

Engine

Power was provided by a 6-cylinder turbocharged diesel engine with 14.7 L (898 cu in) displacement. Rated at about 285 gross horsepower (260 net), the engine delivered nearly 890 lb-ft of torque at 1,400 rpm, giving the machine exceptional dozing strength and reliability under heavy load.

Power Train

The Case 2550 featured a 3-speed full power-shift transmission with three forward and three reverse speeds. Forward travel speeds reached approximately 6.5 mph, with reverse up to 7.5 mph. Heavy-duty planetary final drives ensured durability and consistent power transfer to the ground.

Brakes

Hydraulic wet-disc brakes provided dependable stopping power with minimal maintenance requirements, complemented by a parking brake for added safety.

Hydraulic System

The 2550 used a high-capacity hydraulic system with a 40-gallon reservoir and open-center design. The system powered the large dozer blade and auxiliary attachments with responsive control, even under continuous duty cycles.

Undercarriage

The undercarriage was built for extreme conditions, featuring 8 bottom rollers and 2 carrier rollers per side, with track shoe widths ranging from 24 to 30 inches. Ground pressure averaged about 10 psi, with wider shoes available for soft soils.

Blade and Attachments

The Case 2550 supported a variety of blades, including straight, semi-U, and full U types, with capacities ranging from 10 to 12 cubic yards heaped. Rear attachments such as rippers and winches expanded its utility in mining and land-clearing operations.

Electrical System

The 2550 used a 24-volt electrical system with dual 12-volt batteries and an alternator to power starting, lighting, and auxiliary systems.

Cab and Operator Comfort

The operator’s station was available with ROPS canopy or enclosed cab, with optional heater and air conditioning. Controls were simple yet durable, designed for long working shifts in rugged environments.

Key Highlights

- Production years: Late 1970s – mid 1980s

- Engine: 6-cyl turbocharged diesel, 14.7 L (898 cu in), ~285 HP gross / 260 HP net

- Max torque: ~890 lb-ft @ 1,400 rpm

- Operating weight: ~88,000 lb

- Transmission: 3-speed full power-shift, 3F / 3R; max travel ~6.5 mph forward, 7.5 mph reverse

- Blade capacity: 10 – 12 yd³ (straight, semi-U, U options)

- Track system: 8 bottom rollers, 2 carrier rollers; 24–30 in shoes

- Ground pressure: ~10 psi (varies with shoe width)

- Hydraulic system: ~40-gal reservoir; high-capacity open-center design

- Fuel capacity: 150 gal; Cooling system: 25 gal; Engine oil: 8 gal

- Electrical: 24V system, dual 12V batteries, alternator equipped

- Cab: ROPS canopy or enclosed cab, optional HVAC

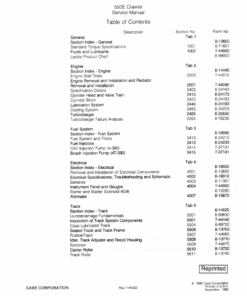

Table of Content

📙 Table of Contents

Contents

- Contents

Introduction

- INTRODUCTION

Engine – 10

- Engine – 10

Hydrostatic Drive – 29

- Hydrostatic drive – 29

Brakes And Controls – 33

- Brakes and controls – 33

Hydraulic Systems – 35

- Hydraulic systems – 35

Tracks And Track Suspension – 48

- Tracks and track suspension – 48

Cab Climate Control – 50

- Cab climate control – 50

Electrical Systems – 55

- Electrical systems – 55

Dozer Blade And Arm – 86

- Dozer blade and arm – 86

Tools – 89

- Tools – 89

Platform, Cab, Bodywork, And Decals – 90

- Platform, cab, bodywork, and decals – 90

Special Tool Index

- SPECIAL TOOL INDEX

Electrical Schematic

- ELECTRICAL SCHEMATIC

Hydraulic Schematic

- HYDRAULIC SCHEMATIC

Specification

| Specification | Case 2550 |

|---|---|

| Years Produced | Late 1970s – mid 1980s |

| Model Type | Crawler dozer (large-frame) |

| Engine Manufacturer / Type | Case / Cummins 6-cyl turbocharged diesel |

| Displacement | 14.7 L (898 cu in) |

| Engine Power (Horsepower) | ~285 gross HP / ~260 net HP |

| Max Torque | ~890 lb-ft @ 1,400 rpm |

| Fuel Capacity | 150 gal |

| Cooling System Capacity | 25 gal |

| Engine Oil Capacity | 8 gal |

| Hydraulic Fluid Capacity | 40 gal |

| Transmission | 3-speed full power-shift (3F / 3R) |

| Max Travel Speeds | Forward: ~6.5 mph; Reverse: ~7.5 mph |

| Operating Weight | ~88,000 lb |

| Blade Capacity (Heaped) | 10 – 12 yd³ (straight / semi-U / U blade options) |

| Track / Undercarriage | 8 bottom rollers, 2 carrier rollers; 40+ shoes per side; shoe widths 24–30 in |

| Dimensions (L × W × H) | Length ~21 ft; Width 12–14 ft; Height ~12 ft |

| Ground Pressure | ~10 psi (varies with shoe width) |

| Electrical System | 24-volt system; dual 12V batteries; alternator equipped |

| Operator Station | ROPS canopy or cab with heater/AC option |

Buyer Questions & Answers

Frequently Asked Questions❔

Are the manuals OEM (Original Equipment Manufacturer)?

- Yes, we only provide manuals that are sourced from the machine manufacturer or authorized dealers.

What file format are the manuals in?

- All manuals are provided in PDF format, which you can be open on your browser, computer, smartphone, or tablet.

- Printed versions are available for select manuals — check the product page or contact us for availability.

Is the manual printable?

- Yes, all pages are printable.

Where do I download the manual after I have paid for it?

- You’ll receive two emails:

- “Your order XXXXX has been received!” – sent immediately.

- “Your order XXXXX is now completed.” – sent within 12 hours with your secure download link.

- If you didn’t get the email:

- ✅ Log In to your Account and check your orders.

- 📂 Check your spam/junk folder.

- 📧 Make sure you didn’t use a different email during checkout.

Still have questions?

- Please Contact Us if you need assistance or have suggestions.

Only logged in customers who have purchased this product may leave a review.

Reviews

There are no reviews yet.