The Case 650M crawler dozer is part of the M-Series lineup, engineered for power, efficiency, and operator-focused performance. Designed with Tier 4 Final technology, hydrostatic drive, and a rugged undercarriage, the 650M is built for grading, pushing, and site-preparation tasks across construction, utility, and agricultural applications.

Introduction

With an operating weight ranging from 15,803 lb (LT) to 16,839 lb (LGP), the 650M provides stability and traction while maintaining compact dimensions for confined job sites. Its Tier 4 Final engine ensures compliance with emissions standards while maintaining productivity and fuel efficiency.

Maintenance – 00

Designed for serviceability, the 650M features ground-level access to filters, fluid reservoirs, and service points. Extended service intervals and simplified diagnostics reduce downtime and operating costs.

Engine – 10

The 650M is powered by an FPT F5C 3.4 L, 4-cylinder turbocharged diesel engine rated at 74 gross horsepower (68 net). This engine provides strong torque output and responsive performance, with a maximum drawbar pull of 39,086 lb for demanding earthmoving operations.

Power Coupling – 19

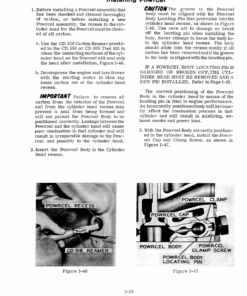

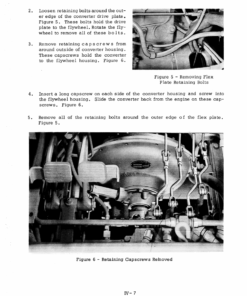

The engine couples to a dual-path hydrostatic drive system, transferring power smoothly to the tracks. This arrangement eliminates shifting, providing precise control and constant power under varying loads.

Hydrostatic Drive – 29

The hydrostatic system allows independent track control with single-lever electronic joystick operation. Operators benefit from infinite speed variability, smooth directional changes, and excellent maneuverability in confined work areas.

Brakes and Controls – 33

The 650M integrates hydrostatic dynamic braking with an automatic spring-applied parking brake. Controls are ergonomic and electronically managed for reduced operator fatigue and enhanced precision during fine grading.

Hydraulic Systems – 35

The open-center hydraulic system delivers approximately 20.3 GPM at 3,000 psi. With sufficient reservoir capacity, the system ensures responsive blade control and reliable performance of attachments under continuous duty cycles.

Hitches, Drawbars, and Implement Couplings – 37

Rear-mounted attachments such as rippers and winches can be installed, increasing machine versatility for site clearing, utility work, and heavy-duty pulling applications.

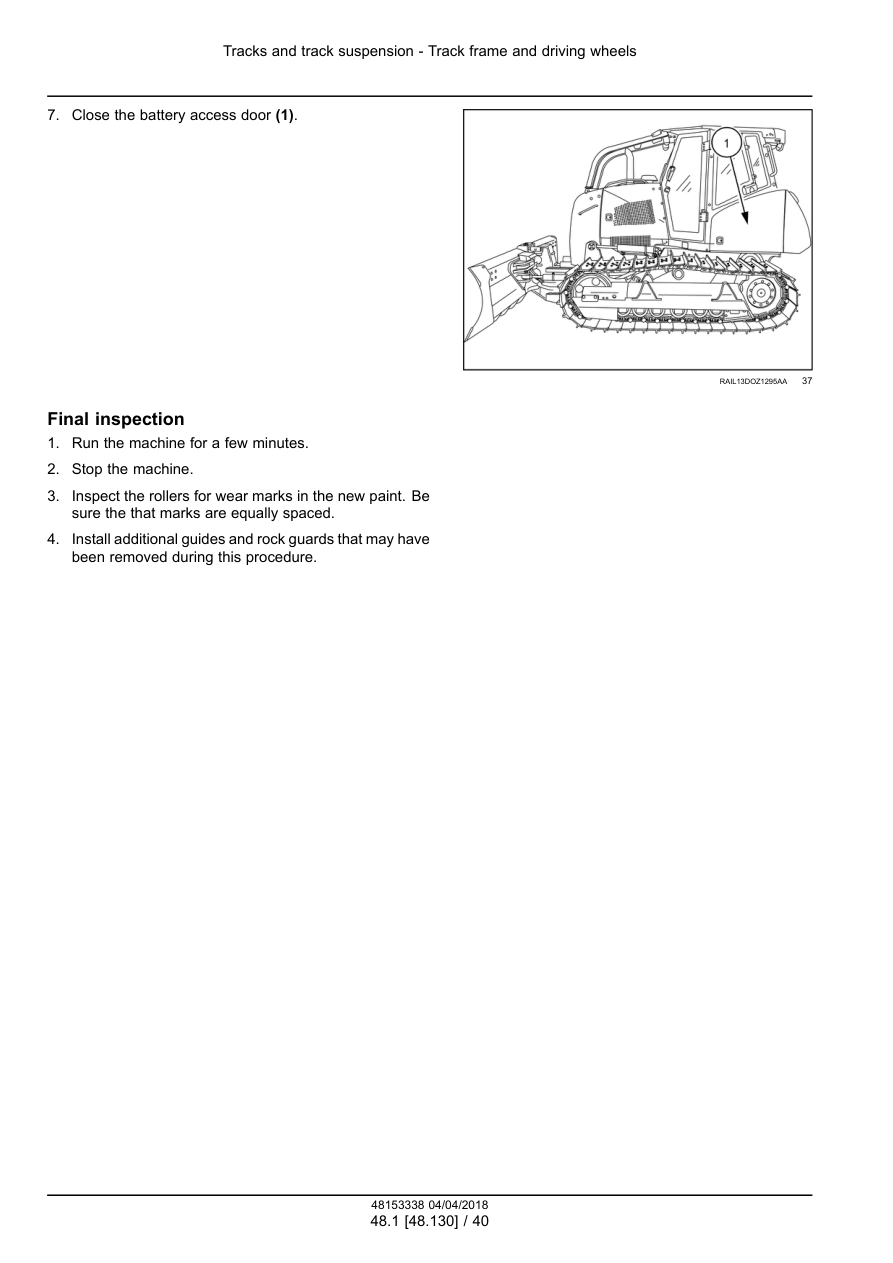

Tracks and Track Suspension – 48

The undercarriage features 85 inches of track on the ground with six rollers per side and 40 shoes per track. Track shoe widths range from 15.6 inches (LT) to 24 inches (LGP), balancing traction, flotation, and ground pressure for different site conditions.

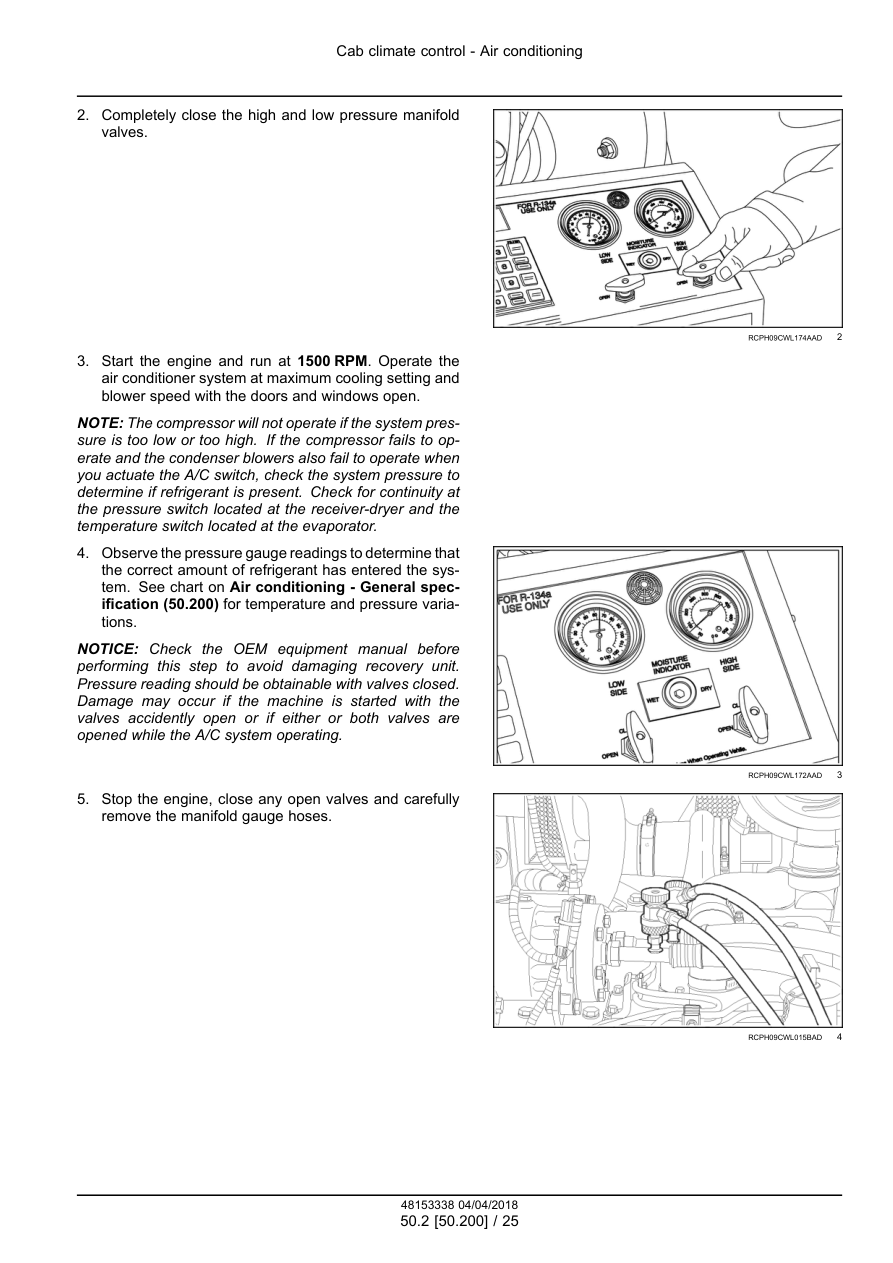

Cab Climate Control – 50

The operator cab is designed for comfort and productivity, with ROPS/FOPS protection, excellent visibility, and available climate control. Heating and air conditioning ensure year-round operator comfort.

Electrical Systems – 55

A 12-volt electrical system with a 120-amp alternator provides reliable starting power and supports lighting, diagnostics, and auxiliary components. The system is robust and designed for long-term reliability in rugged conditions.

Lubrication System – 71

Pressurized engine lubrication and efficient oil circulation ensure reliable cooling and wear protection. Extended oil change intervals reduce downtime and overall maintenance cost.

Dozer

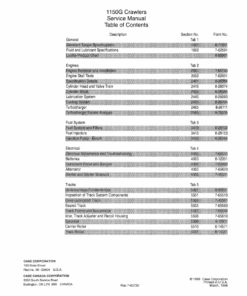

Table of Content

📙 Table of Contents

Contents

- Contents

Introduction

- INTRODUCTION

Maintenance – 00

- Maintenance – 00

Engine – 10

- Engine – 10

Power Coupling – 19

- Power coupling – 19

Hydrostatic Drive – 29

- Hydrostatic drive – 29

Brakes And Controls – 33

- Brakes and controls – 33

Hydraulic Systems – 35

- Hydraulic systems – 35

Hitches, Drawbars, And Implement Couplings – 37

- Hitches, drawbars, and implement couplings – 37

Tracks And Track Suspension – 48

- Tracks and track suspension – 48

Cab Climate Control – 50

- Cab climate control – 50

Electrical Systems – 55

- Electrical systems – 55

Lubrication System – 71

- Lubrication system – 71

Dozer Blade And Arm – 86

- Dozer blade and arm – 86

Tools – 89

- Tools – 89

Platform, Cab, Bodywork, And Decals – 90

- Platform, cab, bodywork, and decals – 90

Special Tool Index

- SPECIAL TOOL INDEX

Electrical Schematic – 48153341

- ELECTRICAL SCHEMATIC – 48153341

Hydraulic Schematic – 48153340

- HYDRAULIC SCHEMATIC – 48153340

Specification

| Specification | Case 650M |

|---|---|

| Years Produced | Mid-2010s (M-Series) |

| Model Type | Crawler dozer (LT/WT/LGP) |

| Engine Manufacturer / Type | FPT F5C F5HFL463D G003, Tier 4 Final diesel |

| Engine Power (Horsepower) | 74 HP (gross); 68 HP (net) |

| Displacement | 207.5 cu in (3.4 L) |

| Fuel Capacity | 40.8 gal |

| Transmission / Drive | Dual-path hydrostatic; single-lever electronic control |

| Maximum Drawbar Pull | 39,086 lb |

| Operating Weight | LT: ~15,803 lb; WT: ~16,405 lb; LGP: ~16,839 lb |

| Hydraulic System | ≈20.3 GPM @ 3,000 psi |

| Blade (Standard) | PAT blade; up to 10 ft width; ~2.2 yd³ capacity |

| Track Undercarriage | Length on ground: 85 in; 40 shoes/side; 6 rollers; variable shoe widths (15.6–24 in) |

| Dimensions | Height to top of ROPS: ~8 ft 8 in; Ground clearance: ~13 in |

| Electrical | 12 V system; 120 A alternator |

Buyer Questions & Answers

Frequently Asked Questions❔

Are the manuals OEM (Original Equipment Manufacturer)?

- Yes, we only provide manuals that are sourced from the machine manufacturer or authorized dealers.

What file format are the manuals in?

- All manuals are provided in PDF format, which you can be open on your browser, computer, smartphone, or tablet.

- Printed versions are available for select manuals — check the product page or contact us for availability.

Is the manual printable?

- Yes, all pages are printable.

Where do I download the manual after I have paid for it?

- You’ll receive two emails:

- “Your order XXXXX has been received!” – sent immediately.

- “Your order XXXXX is now completed.” – sent within 12 hours with your secure download link.

- If you didn’t get the email:

- ✅ Log In to your Account and check your orders.

- 📂 Check your spam/junk folder.

- 📧 Make sure you didn’t use a different email during checkout.

Still have questions?

- Please Contact Us if you need assistance or have suggestions.

Only logged in customers who have purchased this product may leave a review.

Reviews

There are no reviews yet.